Family Owned - USA Proud

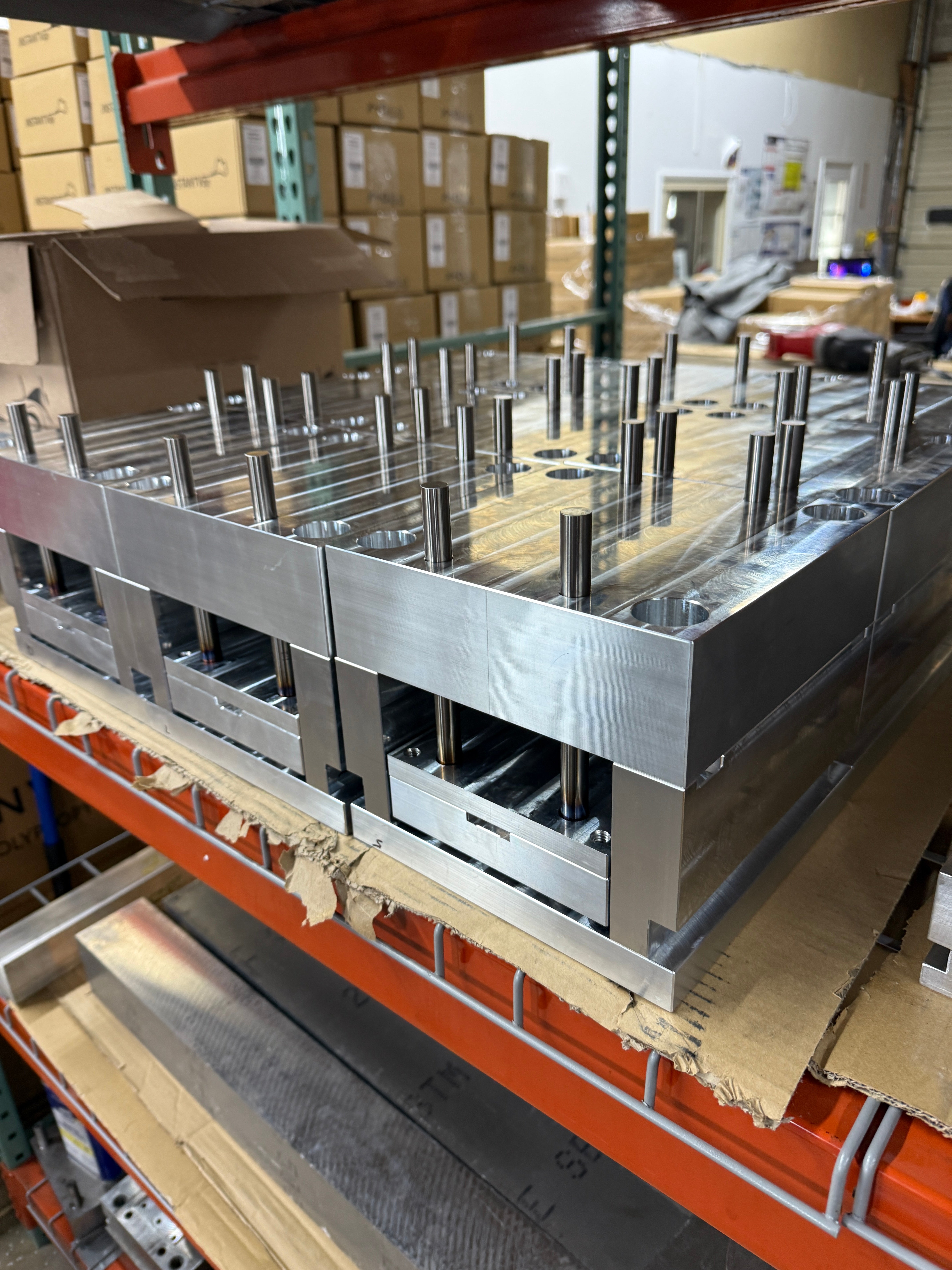

What started as a mission to produce better beekeeping equipment quickly turned into a full-scale injection molding operation focused on quality, repeatability, and control. We design and build molds stateside, run production in-house, and stand behind every part that leaves our shop.

For our beekeeping customers, this means stronger products, better materials, and tighter tolerances.

For our molding clients, it means direct communication, fast revisions, flexible production runs, and real engineering support — not just machine time.

We specialize in small to mid-sized parts, short to mid production runs, multi-color projects, and molds designed for long-term performance. From concept review and mold design to production and fulfillment, everything happens under one roof.

Lorob Bees Manufacturing

Our Process & What to Expect

We keep injection molding simple, predictable, and collaborative from day one. This overview helps you understand timeline, ownership, and how we quote.

Project Review

- We review your part file or concept for manufacturability, material selection, and feasibility.

- Product refinement, shrinkage considerations, and warpage analysis are available on a time and materials basis if needed.

Mold Design

- Mold design is typically completed within a few days depending on complexity.

- We define gating, runner layout, cooling strategy, and the overall tool structure.

- The mold design fee is credited toward mold construction if you choose to proceed.

- After completion and payment, the mold design is delivered in STEP format and becomes your property.

Tooling & Lead Time

- Base mold costs typically begin at $5,000.

- Final tooling pricing depends on complexity, cavity count, material requirements, and tolerances.

- Some molds can be completed in as little as four weeks (more complex tools may require additional time).

- The finished mold/tool remains the property of the customer.

Production Pricing

- Per-part pricing is finalized after mold design is complete.

- We account for confirmed cycle time, resin usage, and runner-to-part volume.

- This approach produces accurate and predictable production costs.

Revisions & Engineering Support

- Product revisions after mold design completion are billed at $125/hr.

- Product modeling and engineering support are available as needed.

- Proper draft is a standard requirement of injection molding and is incorporated during design.

Confidentiality & IP

- NDAs are common in our workflow and are welcomed to protect intellectual property.

- If an NDA allows sharing of manufacturing processes (excluding protected product details), we may share select production clips with the customer’s written approval.

- We never share protected designs or sensitive information without consent.

Note: Timelines and pricing can change with part complexity, resin selection, tolerance requirements, and scope changes.